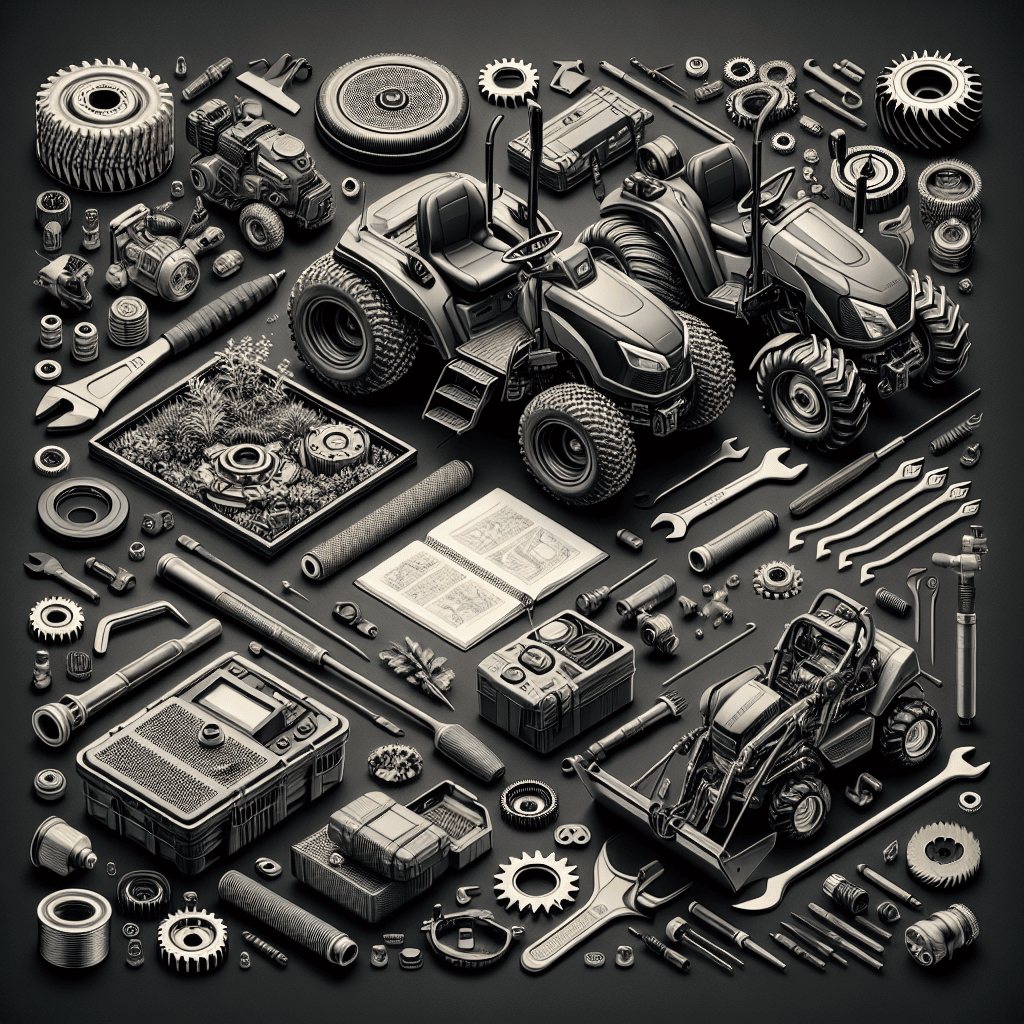

Husqvarna, a renowned name in the world of machinery, offers a diverse range of equipment tailored to meet the needs of various industries, from all-terrain vehicles to mobile and industrial equipment. Known for their durability and performance, Husqvarna machines are essential tools for professionals and hobbyists alike. However, like any piece of machinery, they require regular maintenance and occasional repairs to ensure optimal functionality. This article delves into the different types of Husqvarna equipment, common issues faced by users, and effective repair and maintenance strategies. For detailed manuals and guides, visit Husqvarna Manuals.

Understanding Husqvarna Equipment Types

Husqvarna’s product lineup is vast, encompassing a variety of all-terrain, mobile, and industrial equipment designed to cater to specific tasks and environments. All-terrain models include robust lawn tractors and zero-turn mowers, ideal for tackling diverse landscapes with ease. These machines are engineered for efficiency and precision, making them popular among landscaping professionals and homeowners with large properties.

In the mobile equipment category, Husqvarna offers a range of products designed for mobility and ease of use. This includes chainsaws, trimmers, and blowers that are lightweight yet powerful, catering to both commercial and residential users. The mobility of these tools allows for quick deployment and use in various settings, making them indispensable for tasks that require agility and speed.

When it comes to industrial equipment, Husqvarna provides heavy-duty machines such as construction saws, demolition robots, and surface preparation tools. These machines are built to withstand the rigors of industrial environments, offering reliability and high performance. Understanding the specific type and model of Husqvarna equipment is crucial for effective maintenance and repair.

For those seeking detailed information and user manuals for various Husqvarna models, Husqvarna Manuals is an invaluable resource. This site provides comprehensive guides and specifications that can aid in understanding the intricacies of each equipment type.

Common Issues in Husqvarna All-Terrain Models

All-terrain models, while built for durability, can encounter several common issues that may hinder their performance. One frequent problem is engine trouble, often caused by poor maintenance or fuel quality. Regularly checking and replacing the air filter, spark plug, and oil can prevent many engine-related issues, ensuring smooth operation and longevity of the equipment.

Another common issue is related to the cutting deck and blades. Over time, blades can become dull or damaged, affecting the quality of the cut and putting additional strain on the engine. Regularly inspecting and sharpening or replacing blades can significantly improve the performance of the mower. Additionally, ensuring that the cutting deck is clean and free of debris will help maintain optimal airflow and cutting efficiency.

Transmission problems can also arise in Husqvarna all-terrain models, particularly in older machines. Symptoms such as difficulty in changing gears or unusual noises can indicate a transmission issue. Regularly checking the transmission fluid and ensuring it is at the correct level can prevent many common transmission problems.

For troubleshooting these and other issues, consulting the detailed manuals available at Husqvarna Manuals can provide step-by-step guidance and solutions tailored to specific models and problems.

Mobile Equipment: Repair Strategies and Tips

Husqvarna’s mobile equipment, such as chainsaws and trimmers, requires specific repair strategies to address common issues. One frequent problem is starting difficulty, which can often be attributed to a clogged carburetor or a faulty ignition system. Regular cleaning of the carburetor and checking the ignition components can resolve many starting issues, ensuring the equipment is ready for use when needed.

Another issue often encountered with mobile equipment is chain or line wear. Chainsaws, in particular, require regular tension adjustments and sharpening to maintain cutting efficiency and safety. Similarly, trimmers need their lines replaced regularly to ensure optimal performance. Keeping a maintenance schedule and having spare parts on hand can minimize downtime and prolong the life of the equipment.

Fuel system problems, such as leaks or blockages, can also affect the performance of mobile equipment. Regularly inspecting fuel lines, filters, and tanks for signs of wear and damage can prevent leaks and ensure the equipment operates smoothly. Using the correct fuel mixture and storing equipment properly during off-seasons can also help prevent these issues.

For more detailed repair tips and strategies, Husqvarna Manuals offers comprehensive guides that cover a wide range of mobile equipment models, providing valuable insights and troubleshooting advice.

Industrial Equipment: Maintenance Best Practices

Maintaining Husqvarna’s industrial equipment involves adhering to best practices that ensure the machines operate efficiently and safely. Regular inspections are crucial, focusing on critical components such as blades, belts, and hydraulic systems. Identifying wear and tear early can prevent costly repairs and extend the equipment’s lifespan.

Lubrication is another key aspect of maintaining industrial equipment. Ensuring that all moving parts are adequately lubricated reduces friction and wear, improving the overall performance and reliability of the machinery. Following the manufacturer’s lubrication schedule and using the recommended lubricants is essential to prevent damage and ensure optimal operation.

Safety checks are vital when dealing with industrial equipment. Regularly inspecting safety features such as guards, emergency stops, and warning systems ensures that the equipment remains safe for operators. Training operators on proper usage and maintenance procedures can also reduce the risk of accidents and equipment failure.

For detailed maintenance procedures and guidelines, Husqvarna Manuals provides extensive resources tailored to various industrial equipment models. These manuals offer valuable insights into maintaining the equipment in peak condition and ensuring compliance with safety standards.

Husqvarna equipment, renowned for its durability and performance, is a valuable asset across various industries. However, regular maintenance and timely repairs are crucial to keep these machines running at their best. By understanding the specific needs of different equipment types and addressing common issues promptly, users can ensure the longevity and efficiency of their Husqvarna machines. For comprehensive manuals and guides, Husqvarna Manuals serves as an essential resource, providing detailed information to support effective maintenance and repair practices.